Hardware valves need to be automated through design and development

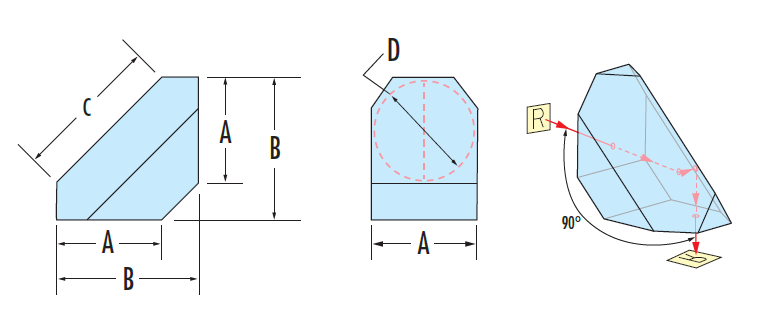

AMICI reflection prism called also roof prism or right angle roof prism,which deflects the beam through an angle of 90 degree and inverts the image. For this reason,this prism is perfect for erecting images inverted by the objectives. We supply many types of high precision optical prisms,such as Wedge Prism,Right Angle Prism,rhombohedral prism,Dove prism,Penta prism,pyramid prism,dispersing prism,Reflection prism etc. Each having a particular geometry to achieve the reflections necessary to perform a specific imaging task.Reflecting prisms may invert,rotate,deviate or displace a beam.dispersing prisms produce spectral separation for spectroscopic applications or for tuning a laser output.Wedge prism is commonly used in laser system for eliminating the reflections from the second surface or for beam steering.Irregular-shaped or non-standard size prisms may be available by custom order. Specification of our Amici roof prism as follow: *Material BK7 Grade A optical glass,UV fused silica,MgF2,N-SF10 etc. Roof Prism,Polished Roof Prisms,Amici Roof Prism,Right Angle Roof Prism China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com The global valve industry has increasingly shifted to China, bringing significant growth in production capacity and elevating the overall level of China's valve sector. This shift has also boosted the visibility of Chinese valve manufacturers and expanded their share in the international market. However, despite this progress, the industry still faces challenges due to structural imbalances and limited innovation capabilities. As a result, the sector has encountered stagnation, with many companies struggling to move beyond basic manufacturing.

Currently, the marketing strategies of most Chinese hardware valve companies remain at an early stage compared to global standards. There is a lack of strong brand identity, limited technological innovation, and no control over the industrial chain. Many firms rely on narrow sales channels, with weak awareness of resource integration. Additionally, they lack effective methods for managing product quality and on-site production, making it difficult to maintain consistent standards.

Low-end valves are no longer sufficient to meet future demands. To drive sustainable growth, the focus must shift toward advanced design and R&D. This will not only promote the establishment of automation technology innovation centers but also support the transformation of traditional valve industries. Developing high-end products such as bellows globe valves, control valves, and regulating valves will help elevate the industry’s technical level. At the same time, efforts should be made to nurture leading enterprises and build a national brand with global influence, ultimately strengthening China's position in the global valve market.

In contrast, the valve industries in Europe and the U.S. have built their success on principles like quality, fair profit-sharing, customer service, and corporate reputation. These countries organize, educate, and manage their enterprises with strict control over each project and production process, ensuring the quality and performance of every valve. Such practices have created a significant gap between China and these developed nations. To close this gap, China must invest more in innovation, quality control, and long-term strategic planning.

The global valve industry has increasingly shifted to China, bringing significant growth in production capacity and elevating the overall level of China's valve sector. This shift has also boosted the visibility of Chinese valve manufacturers and expanded their share in the international market. However, despite this progress, the industry still faces challenges due to structural imbalances and limited innovation capabilities. As a result, the sector has encountered stagnation, with many companies struggling to move beyond basic manufacturing.

Currently, the marketing strategies of most Chinese hardware valve companies remain at an early stage compared to global standards. There is a lack of strong brand identity, limited technological innovation, and no control over the industrial chain. Many firms rely on narrow sales channels, with weak awareness of resource integration. Additionally, they lack effective methods for managing product quality and on-site production, making it difficult to maintain consistent standards.

Low-end valves are no longer sufficient to meet future demands. To drive sustainable growth, the focus must shift toward advanced design and R&D. This will not only promote the establishment of automation technology innovation centers but also support the transformation of traditional valve industries. Developing high-end products such as bellows globe valves, control valves, and regulating valves will help elevate the industry’s technical level. At the same time, efforts should be made to nurture leading enterprises and build a national brand with global influence, ultimately strengthening China's position in the global valve market.

In contrast, the valve industries in Europe and the U.S. have built their success on principles like quality, fair profit-sharing, customer service, and corporate reputation. These countries organize, educate, and manage their enterprises with strict control over each project and production process, ensuring the quality and performance of every valve. Such practices have created a significant gap between China and these developed nations. To close this gap, China must invest more in innovation, quality control, and long-term strategic planning.

*Dimension:3-100mm.

*Dimension Tolerance +/-0.2mmÂ

*Beam Deviation Up to 30 arc secondsÂ

*Angle Tolerance Up to 5 arc secondsÂ

*Flatness Up to λ/4 @633nmÂ

*Surface Quality 60/40 scratch and dig,40/20 even better

*Chamfer 0.3mm+/-0.1mmÂ

*Coating: AR coating,HR,PR upon request.Â